Customised Chambers :: Automotive

The Automotive industry drives standards development through the creation and adoption of innovative test methods based on decades of field-experience. These new methods often require modifications to existing test equipment to provide the performance required. Espec has a long history of supporting these tests and the chambers featured on this page showcase some of the semi-custom models available on request.

From LV-124 K-14 Condensation tests to brake-oil resistance chambers Espec has the experience to design the chamber you need.

LV124 K14 BMW Condensation Test Chamber

L 124 is a quality and reliability test standard jointly established by German automotive manufacturers.

This standard has become the most important test standard for the global automotive industry.

This chamber is used to evaluate the resistance of electronic components and assemblies to condensation by condensation phase and drying phase.

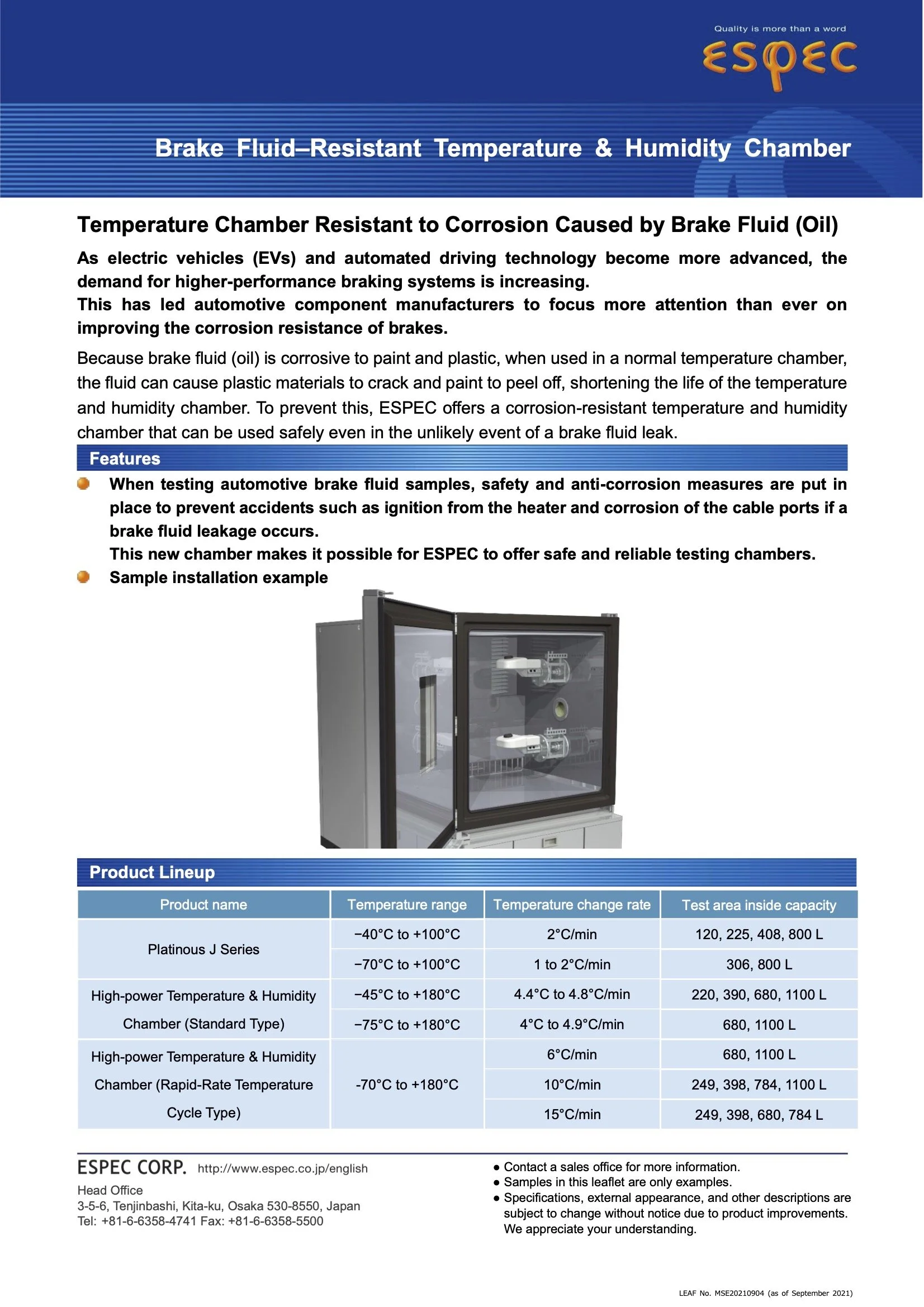

Brake Fluid Resistant Environmental Test Chamber

Because brake fluid (oil) is corrosive to paint and plastic, when used in a normal temperature chamber, the fluid can cause plastic materials to crack and paint to peel off, shortening the life of the temperature and humidity chamber. To prevent this, ESPEC offers a corrosion-resistant temperature and humidity chamber that can be used safely even in the unlikely event of a brake fluid leak.

Salt Mud Water Spray Test Chamber

There are many safety devices are now being developed and installed in vehicles, including automatic brake systems.

Sensors mounted on the exterior of the vehicle are exposed not only to temperature and humidity, but also corrosive agents.

In order to reproduce this environment, this chamber is equipped with a salt-mud sprinkling system in addition to the conventional temperature and humidity.

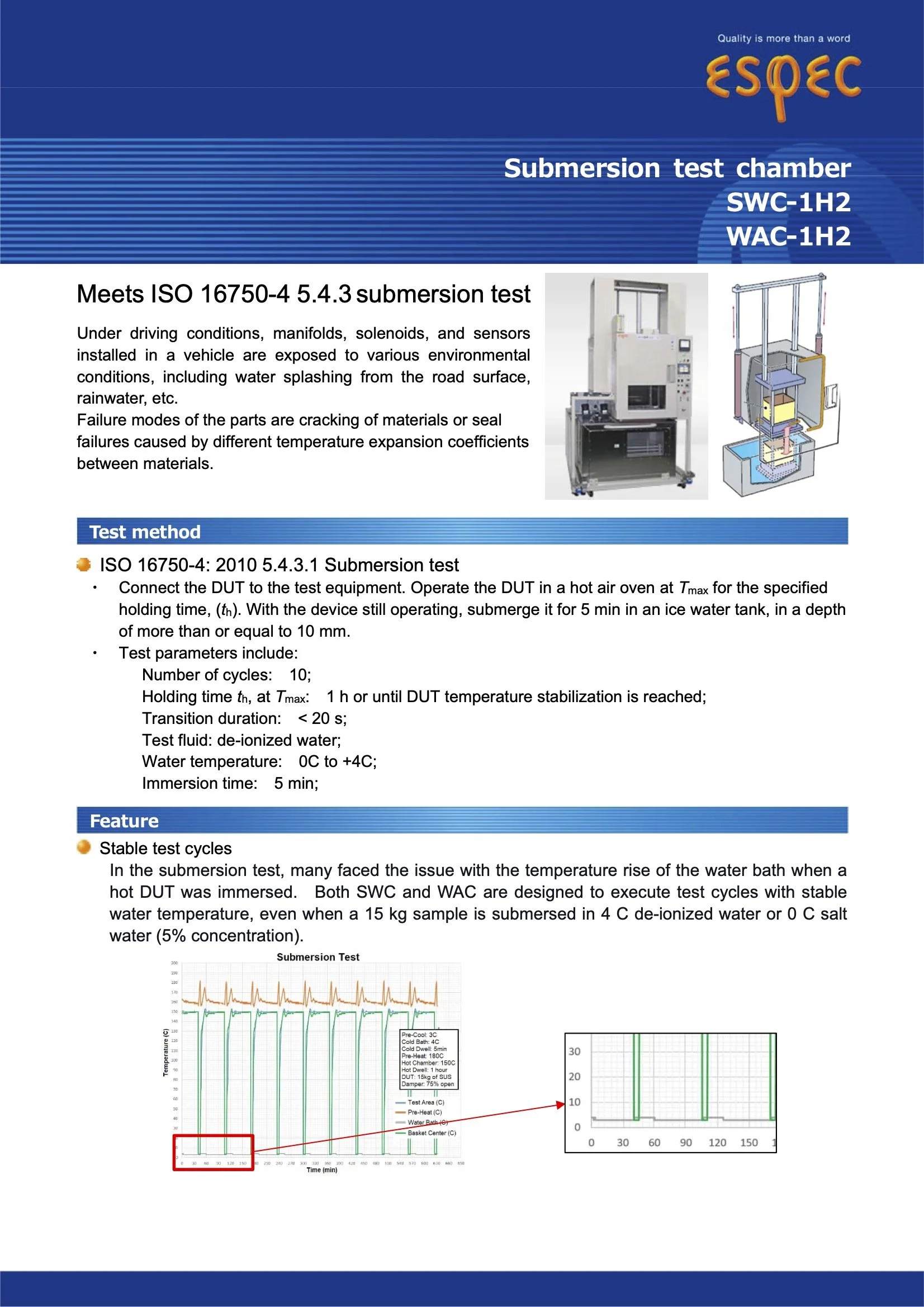

ISO16750 Submersion Test Chamber

When driving items such as manifolds, solenoids, and sensors installed in a vehicle are exposed to various environmental conditions, including water splashing from the road surface, rainwater, etc.

Failure modes of the parts are cracking of materials or seal failures caused by different temperature expansion coefficients between materials. These chambers accelerate the failure mode using submersion.

Automotive VOC Test Chamber for Outgassing

ESPEC produces a drive-in chamber dedicated to VOC evaluation, which has various measures to suppress VOC generation from the chamber itself, and includes a solar simulator to perform accurate VOC measurements inside the vehicle.

These chambers allow customers to measure these VOC and determine where they’re coming from, and if they’re being processed out of the vehicle, or concentrated within it.

LV-124 Compliant Test Chambers

LV 124 is a quality and reliability test standard jointly established by German automotive manufacturers in 2013.

LV 124 applies to in-vehicle electric components for the 12V electrical system - Electric, electronic, and mechatronic components and systems

Espec manufacture a range of chambers to support our customer meet these stringent test requirements.