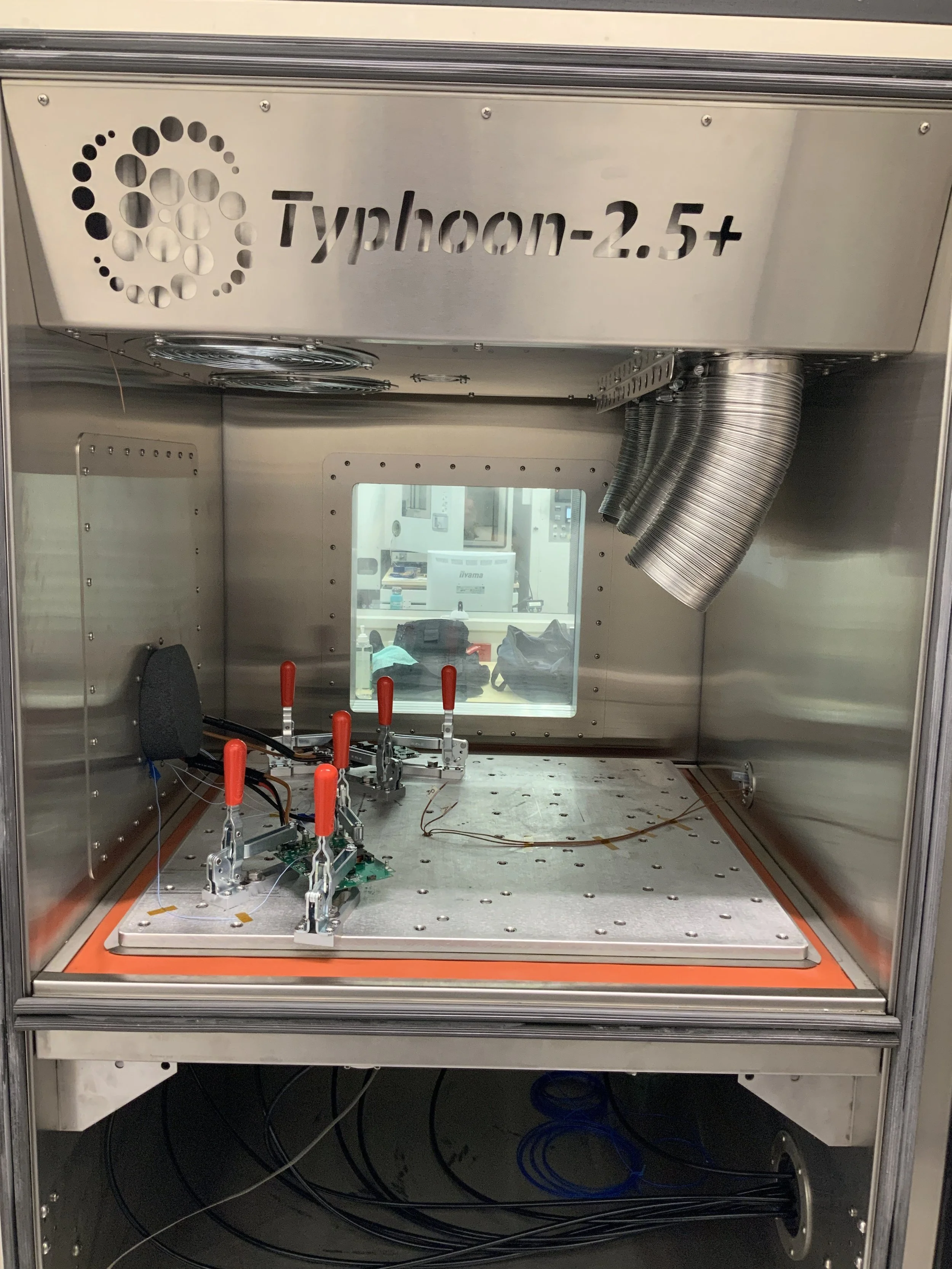

Qualmark Typhoon 2.5+ HALT Chamber (LN2)

The Qualmark Typhoon 2.5 is the most popular chamber in the Accelerated Stress Test (AST) Industry. Its 30” x 30” vibration table size is optimal for Highly Accelerated Life Testing (HALT) applications as well as many Highly Accelerated Stress Screening (HASS) applications. Designed with Typhoon technology which has the lowest total costs of ownership (TCO), the 2.5 is a multi-tasking system with over 325 produced for rapid ROI in both design and production engineering environments.

Qualmark HALT testing systems (Highly Accelerated Life Test) combine extreme temperature cycling and repetitive-shock/vibration for the ultimate in accelerated reliability testing. The technology has matured from a simple thermal shock chamber with a vibration table to an integrated testing system. Qualmark chambers have been the market leader in HALT since introducing the technology in the early 1990s. Today, our technology continues to reflect the best advances in HALT/HASS system testing. Our models are the most energy-efficient on the market. The technology provides the extreme stresses necessary to rapidly find design flaws missed by traditional methods.

We specify, quote, install and service these machines Australia-wide.

6DOF repetitive-shock table

Simultaneous excitation at multiple frequencies for testing complex assemblies

Patented pneumatic hammer/table design is lubrication-free and valveless

Quiet operation without external cooling requirements

The table is field-adjustable for resetting to original PSD levels, ensuring consistent performance. (Adjustment included in our preventative maintenance agreement.)

Cooling System

Vacuum Jacketed (VJ) liquid nitrogen (LN2) valves and manifold.

Proportional control and valve system for maximum LN2 efficiency and consistent temperature control, while reducing two-phase (gas/liquid) states that cause problems in traditional on/off solenoid-based control.

VJ eliminates condensation, dripping water, OSHA safety concerns, and energy loss compared to other insulation methods.

Efficient, economical LN2 usage with either low-pressure Dewar tanks or higher pressure Permacyl and bulk tank systems.

Chamber Design

Stainless steel interior, painted exterior, with two full opening doors (one door on T1.5/2.0 models)

High-velocity airflow for improved product temperature change rates.

Two-position table for flexibility to test taller samples, improved ergonomics, and less LN2/electricity usage for smaller test items. (except T1.5/2.0)

Advanced chamber insulation combined with our low-noise hammers results in very quiet operation, even at maximum vibration levels.

Adjustable feet for leveling unit (stand options for T2.5/3.0 models)

Control System

Microsoft Windows system with Labview based operation and PLC-based controls

Programming, operation, and datalogging for vibration/thermal profiles.

One accelerometer for table control (three additional inputs available)

Two thermocouples: one for product, one for air (four additional inputs available)

Eight event relays for external controls

Optional Q-Link or Qualview software tools for ATE integration and other remote connections.

Optional integrated spectrum analyzers and data acquisition systems.

Liquid Nitrogen Vacuum Jacketed Piping

We work with your facilities teams to specify, design and supply the pipework for your HALT chamber.

Keep-full devices are essential to ensure optimum control of the chamber - preventing gas from creating PID disturbances.

Our pipe is made in the USA by Midwest Cryogenics and is simple to install and maintain.

Exhausts, airlines, and all other chamber utility requirements can be supplied.

External control and safety valves can be fitted to shut off supply in the event of a leak.

Safety Systems

We understand the risks of Liquid Nitrogen and have decades of experience planning installations and the safety mitigations that go with them.

Control panels inside the room are tied to gas detectors which can automatically shut the chamber supply line down at the source.

Control valves can be placed at key points along the route to ensure sections can be isolated through key facilities.

Additionally the control panels can be tied to facility supply and exhaust systems to increase air flow before critical alarms kick in and take the building down.

HALT Chamber Specifications (Qualmark Typhoon 2.5)

| Qualmark HALT | T2.5 |

|---|---|

| Interior Volume | 24.8 cu. ft. 702.6 Liters |

| Interior Dimensions (W x D x H) |

35" x 35" x 35" 889 x 889 x 889 mm |

| Exterior Dimensions (W x D x H) |

46.8" x 61.6" x 82.1" 1188 x 1564 x 2085 mm |

| Temperature Range | -100 to 200°C -148 to 392°F |

| Average Change Rate (lower with 50Hz power) |

70-100°C/min

|

| Repetitive Shock | Vibration Acceleration: 5 - 75 gRMS (bare table) |

| Power | 380/400/440/480V 60A max |

| Maximum Sound Level (1 meter away) |

73 dBA at 50 gRMS dBA |

| Notes | Table size: 30" x 30" (762 x 762mm); 8 actuators |