Compact Electrodynamic Shakers (IMV m-Series)

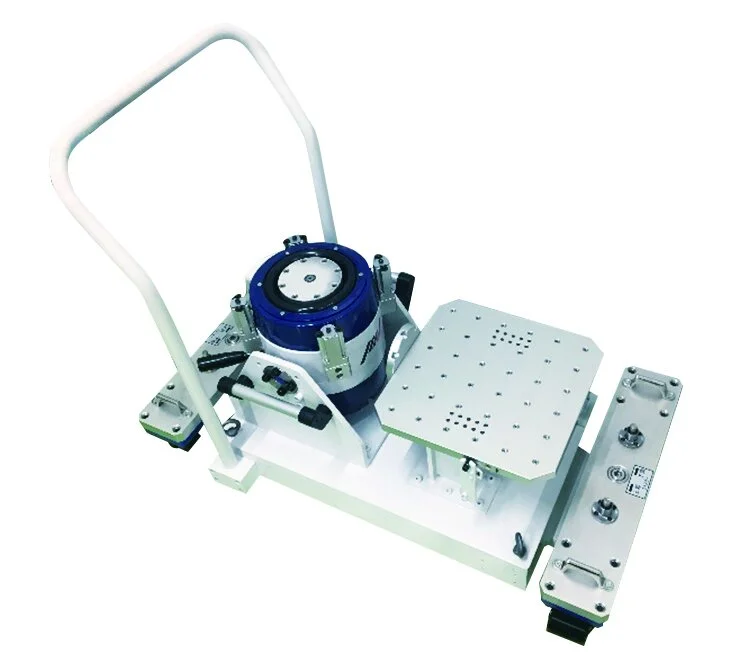

The m-Series range of Electrodynamic Shakers is both compact and silent, but still powerful enough for full-scale tests. The m-Series shaker is small enough to be moved safely by an end-user using integrated carrier handles and is quiet enough to operate without major sound-proofing expense.

Cooling is provided by the built-in Cooling Fan, that is DC-Powered. There is also the availability of Natural Air Cooling (with a limitation on performance) giving the system a form of resilience. The compact shaker system, by design, features noise reduction and doesn’t require an external blower.

Further benefits to the compact design include low power consumption when compared to a larger system, uncompromising high-precision measurement and flexible enough to adapt to almost any test environment. The compact shaker from IMV is ideal for test environments that are noise sensitive and have limited space.

All compact systems can be offered with head expander and slip table options. You can also combine the m-series compact vibration test system with a thermal and humidity chamber.

Applications include both multi-axis and squeak and rattle.

Feature Summary

Random Vibration

Conduct random testing using traditional methods, or go further using Kurtosis control to increase “peakiness”. Random-on-Random and Sine-on-Random also available.

Sine Vibration

Everything you expect in a vibration controller and more - sine sweeps, dwells, single points, amplitude dwell, resonance search and more.

Classical Shock + More

Classical shock waveform (Half-sine, Haversine, Saw-tooth, Triangle, Trapezoid), Sine beat waveform, Measured waveforms

Sine Burst + Beat

Commonly required in aerospace testing these waveforms are optionally supported with software licensing.

International Safety Standard Compliant

The MA1-CE amplifier incorporates a range of safety features, making them compliant for world-wide deployment.

Squeak & Rattle Testing

This type of test is becoming increasingly important as the requirements for interior noise in electric vehicles continue to increase. Previously combustion engines drowned out many of these sounds - not anymore with EVs.

Multi-Axis Support

A range of small-size systems, including 2-axis and 3-axis simultaneous systems, employing the popular m-series vibration generators and patented Integrated Cross Coupling Bearing Unit (ICCU) multi-axis armature / load support technology.

Head Expanders

The little M-series can handle decent weight - head expanders can be provided with additional support guides to allow for larger samples.

Datasheets: IMV m-Series Vibration Test Systems

Model Summary: m-Series

| System Model | m030/MA1-CE | m060/MA1-CE | m120/MA1-CE | m030H/MA1-CE |

|---|---|---|---|---|

| Frequency Range (Hz) | 0-3000 | 0-3000 | 0-2000 | 1000-10000 |

| Rated Force Sine (N) | 300 | 600 | 1200 | 380 |

| Rated Force Random (N rms) | 210 | 420 | 840 | 266 |

| Rated Force Shock (N) | 300 | 600 | 1200 | 380 |

| Max. Acc. No load (m/s2) | 500 | 500 | 500 | 200 |

| Max. Acc. 0.5kg load (m/s2) | 272 | 352 | 413 | 158 |

| Max. Acc. 1.0kg load (m/s2) | 187 | 272 | 352 | 131 |

| Maximum Velocity (m/s) | 1.6 | 1.6 | 1.6 | - *1 |

| Maximum Displacement (mmp-p) | 26 | 30 | 30 | - *1 |

| Maximum Load (kg) | 15 | 15 | 120 | 15 |

| Power Requirements (kVA) *2 | 0.4 | 0.7 | 1.1 | 0.5 |

| Vibration Generator | m030-CE | m060-CE | m120-CE | m030H-CE |

| Armature Support Method | Diaphragm spring | Diaphragm spring | Diaphragm spring | Rubber spring |

| Armature Mass(kg) | 0.6 | 1.2 | 2.4 | 1.9 |

| Armature Diameter(Dmm) | 114 | 114 | 174 | 65 |

| Dimensions(mm) | D190xH240 | D230xH281 | D320xH327*3 | D190xH275 |

| Mass(kg) | 22 | 40 | 110 | 30 |

| Power Amplifier | MA1-CE | MA1-CE | MA1-CE | MA1-CE |

| Maximum Output (kVA) | 1 | 1 | 1 | 1 |

| Dimensions (mm)WxHxD | 430x149x430 | 430x149x430 | 430x149x430 | 430x149x430 |

| Mass (kg) | 25 | 25 | 25 | 25 |

| Air cooling | Air cooling | Air cooling | Air cooling | Air cooling |

| Blower | Housed in vibration generator | Housed in vibration generator | Housed in vibration generator | Housed in vibration generator |

*1 The displacement at the lower limit of frequency (1000Hz) and maximum acceleration (200m/s2) is so small that there is no certified value.

*2 Power supply: single-phase 200-240 V, 50/60 Hz. A transformer is required for other supply voltages.

*3 Insulation pad (W410 x H45 x D410 mm) is standard equipment.

* The specification shows the maximum system performance. For long-duration tests, de-rating by up to 70 % must be applied. Continuous use at maximum levels may cause failure. Please contact IMV if you use more than 70 %.

* Frequency range values vary according to sensor and vibration controller.

View full specifications here: https://www.imv-global.com/specifications/?lang=en

Model Specification: Head Expanders

| Model | Dimensions (mm) | Mass(kg) | Maximum Frequency (Hz) | m030-CE | m060-CE | m120-CE |

|---|---|---|---|---|---|---|

| TBV-125-_-A | 125_125_t20 | 0.9 | 2000 | _ | _ | |

| TBV-200-_-A | 200_200_t20 | 2.5 | 1500 | _* | _ | _ |

| TBV-315-_-A | 315_315_t30 | 8.5 | 1000 | _* | _ | |

| *TBV-400-_-A | 400_400_t35 | 14.4 | 600 | _* |

Model Specification: Slip Tables

| Model | Dimensions (mm) | Maximum Frequency (Hz) | Mass (kg) | ||

|---|---|---|---|---|---|

| m030-CE | m060-CE | m120-CE | |||

| TBH-200 | 200×200 | 500 | 4 | 4 | 5.5 |

| TBH-315 | 315×315 | 500 | 7.5 | 7.5 | 9 |

| TBH-400 | 400×400 | 500 | ━ | 12.3 | 14 |

“-A” at the end of model number shows that material is aluminum alloy.

Add the vibration generator type where “□” is shown.

* The supplementary guidance system using linear bearings is used with the vibration generator when combined with the head expander.

View full specifications here: https://www.imv-global.com/specifications/?lang=en