We keep things simple - we provide highly reliable, accurate and performant test equipment to Australia.

A modern take on Air-to-Air Thermal Shock Chambers - the specimen stays still whilst zones are switched using dampers. The TSA series is designed to evaluate reliability of test specimens by rapid change of the air temperatures from hot to cold repeatedly by opening and closing of damper in a single test area.

Large format thermal shock testing caters towards full assembly tests on items like lithium ion battery packs for the EV market, and complete sub-assemblies for the defence industry. Designed to evaluate reliability of test specimens by rapid change of the air temperatures from hot to cold repeatedly by opening and closing of damper in a single test area.

Liquid to liquid thermal shock testing applies thermal shocks to test samples by alternately immersing them in a high- and low-temperature liquid medium. Since a liquid is used as the thermal medium, this type of testing can attain a sharper temperature variation rate than air to air thermal shock testing.

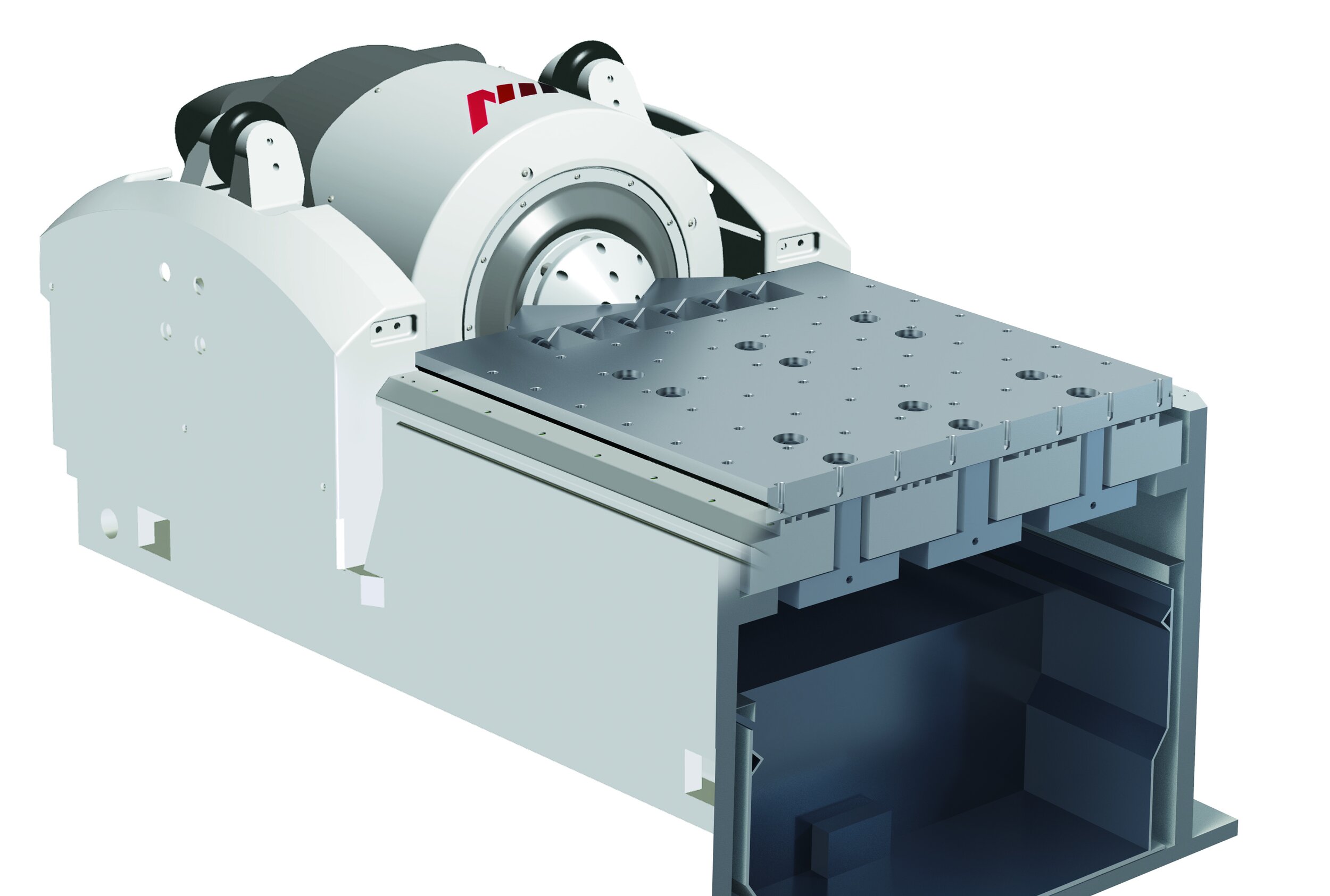

Multiple position combined test chambers support vertical, horizontal and stand-alone configurations, covering every use-case for single-axis shake and bake testing.

What’s better than being able to test in all three orthogonal axis using a combined environment chamber? Multi-axis shakers under AGREE chambers provide even faster acceleration of test results and mimic the real world.

Simple Z-Axis only chambers can be easily integrated with standard shaker systems from any manufacturer - or with a new system to your specification.

IMV make some seriously large AGREE test chambers, supporting combined environment testing for whole vehicle/structure testing for the automotive and defence industry. Very large specimens can be tested using these systems, and the rooms can be built on-site to take advantage of available space (or limitations).

IMV M-Series small-format Electrodynamic Shakers can conduct Squeak & Rattle noise studies on vehicles. Thanks to the extremely quiet shaker, acoustic experiments can be carried out with high accuracy.

The A-series represents the cutting edge of vibration testing systems. Incorporating patented technology to increase axial stiffness and a range of improvements on power use and efficiency it’s the ideal solution for todays vibration testing needs.

IMV’s Multi-axis vibration test technology is at the cutting edge of Vibration Test & Measurement solutions available on the market today. Multi-axis test systems provide the end-user with accurate results in a realistic and convenient manner. It is possible to achieve far greater efficiency when testing in all axis.

The K-series provides maximum performance in a range of sizes from 30kN all the way to 350kN providing high performance and load support for large and complex assemblies. Being water cooled these shakers are quiet, with the fan noise associated with shake-table testing all but eliminated.

The K2+ is the latest MIMO vibration controller from IMV Corporation, allowing for control of up to 4 shakers at one time. The system includes everything you’d expect from a vibration controller - including non-gaussian kurtosis random control.

The J-series offers high displacement and power for long duration and high velocity shock pulses in addition to high intensity low-frequency vibration.

The C-Series transport electrodynamic shakers have serious load carrying potential and have been designed to conduct transport testing with a 76.2mm throw. The C10 provides the same load support as the huge A74 74kN shaker.

Customers wishing to take advantage of the ECO technology offered by IMV are able to upgrade their equipment through the ECO Replacement Amplifier Program.

Shielded / Anechoic test chambers with temperature control for 5G and other radio-related fields. These chambers provide a radio quiet environment for assessing product performance over thermal stress.

ESPEC’s Platinous J-series chambers are the result of more than 50 years of environmental chamber design and development - premium materials and ultimate stability are the hallmarks of this chamber.

Temperature change rates from of 4, 5, 10, 15 or 18K/minute cover a wide range of automotive and aerospace requirements. The AR series supports a wide temperature range and is at ease with high heat load rejection.

ESPEC’s bench-tops can fit on a personal desk - this small temperature and humidity chamber achieves high performance to fulfil your environmental testing needs.

Walk-In Chambers are used in a wide range of research and development related to people and the environment. They require high specifications that can satisfy strict reliability tests for vehicles and other applications.

ICH Stability test compliant chambers for quality control testing on pharmaceuticals, medical supplies, cosmetics, food and packaging materials.

With their highly efficient refrigeration system and outstanding thermal insulation, ESPEC's constant climate cabinets are ideal for use in laboratories and research facilities.

Choose from 2 different capacities (1m³ and 2m³) of the VOC Emission Test Chamber according to the size of the specimen. You can perform VOC emission testing in various fields, from compact specimens to large specimens.

These new Qualmark HALT system with ESPEC cascade refrigeration eliminate the need for liquid nitrogen (LN2), making basic HALT testing possible for customers and locations where traditional HALT systems just aren’t feasible.

The Qualmark Typhoon 2.0, with its 24” x 24” vibration table, is perfect for performing Highly Accelerated Life Testing (HALT) on small products, or where limited lab space is available. This compact system is built using Qualmark’s Typhoon system technology which delivers impressive thermal performance and six-degree-of-freedom repetitive-shock vibration, and is highly efficient in LN2 usage and power consumption. The Qualmark Typhoon 2.0 is a practical addition to any company’s product reliability program.

ESPEC's Qualmark T3.0 is specifically designed to help the customer who is performing low volume Highly Accelerated Stress Screens (HASS) and needs a chamber with a 36"× 36" vibration table. It is also ideal for performing Highly Accelerated Life Tests (HALT) on mid-sized and larger products. The T3.0 vibration table mounts at two different heights, so the interior chamber volume can be adjusted for the needs of the product.

The Qualmark Typhoon 2.5 is the most popular chamber in the Accelerated Stress Test (AST) Industry. Its 30” x 30” vibration table size is optimal for Highly Accelerated Life Testing (HALT) applications as well as many Highly Accelerated Stress Screening (HASS) applications. Designed with Typhoon technology which has the lowest total costs of ownership (TCO), the 2.5 is a multi-tasking system with over 325 produced for rapid ROI in both design and production engineering environments.

Qualmark’s QFusion™ (patent pending) HASS Chamber ushers in a new era of product reliability management during the manufacturing process. By fusing accelerated stress testing and Burn-in into one powerful system, Qualmark has engineered breakthrough technology that incorporates the best of traditional and accelerated production stress screening.

The Qualmark Typhoon 4.0 is designed specifically for the task of performing Highly Accelerated Stress Screening (HASS) and HALT on large products. With the Lowest Total Cost of Ownership within the AST industry, the 48” x 48” vibration table is capable of supporting hundreds of pounds of products and fixturing, and delivers more energy in the lower frequency ranges necessary to stimulate failures in these large products.

The Qualmark Typhoon 8.0 doubles the width of our popular Typhoon 4.0 chamber. The thermal system in the Typhoon series has been carefully engineered to have superior thermal efficiency. Key design elements such as our patented blower technology, highly efficient air flow characteristics and careful choice of materials have combined to keep liquid nitrogen and electricity costs down without compromising our industry standard thermal performance.

The OVTT (Qualmark Benchtop Repetitive-Shock Table) is the first stand-alone, table-top, repetitive-shock vibration system on the market. The OVTT system is ideal for No Fault Found (NFF) precipitation screens of field returns, repair verification, and random vibration test of small products. The Qualmark OVTT system utilizes our patented six-degree-of-freedom vibration technology and has reduced air requirements and low noise levels.

The Model 1000 Vibration Test System is best suited for testing small products or packages.

The complete system features a table sized to your application, a rugged hydraulic actuator, a reliable hydraulic power supply, and Lansmont’s TouchTest Vibration Controller.

The Model 1800 Vibration Test System is our most popular model. It is a good fit for many product and package testing applications.

The complete system features a table sized to your application, a rugged hydraulic actuator, a reliable hydraulic power supply, and Lansmont’s TouchTest Vibration Controller.

The Model 10000 Vibration Test System is designed for testing large, heavy payloads. The actuator force and large table options make the Model 10000 the ideal vibration system for testing unit loads and large crated products.

The Model 10000 performs testing per ASTM, ISTA, ISO and other common industry test specifications. The system will also run test profiles created from SAVERTM environmental data.

Our PDT 80 Precision Drop Tester is our most popular model. With a handheld controller and electric hoist for positioning of the drop assembly, the PDT 80 it can be used for a variety of drop testing requirements. The PDT 80 consists of a drop leaf assembly housed in a cast aluminum structure. The drop leaf housing is supported by a 3 in. (7.6 cm) diameter chrome-plated steel guide rod that is mounted to the 0.5 in. (1.3 cm) thick steel base plate.

The PDT 300 utilizes a welded steel drop carriage, guided by precision bearing assemblies on a structural steel guide beam. The drop carriage is raised and lowered by an electric hoist. During the drop test, the drop carriage is accelerated downward, allowing the test item to free fall.

The PDT 700 facilitates precision drop testing of large test items weighing up to 1540 lbs. (700 kg). Similar to the PDT 300 design, the larger PDT 700 utilizes a welded steel drop carriage, guided by precision bearing assemblies on a structural steel guide beam. A hoist system raises and lowers the drop carriage to easily and safely move heavy test items.

Designed to evaluate box performance, the SqueezerPro is a valuable investment for researching the effects of various board mediums, closures, interior partitions, and other box design variables on compressive strength performance.

The SqueezerPro can also be used for distribution simulation compression testing on individual packages.

The Model 122-15 is a servo-hydraulic compression tester designed to evaluate the compressive strength of individual shipping containers as well as larger pallets, unit loads, and large bulk containers.

The standard system has a platen size that is 60 in. (152 cm) square with a maximum opening of 84 in. (213 cm). Optional extended platens and larger openings are available to accommodate larger test items. Maximum force capability is 30,000 lbs. (133 kN).

The Model 152-30 can be installed on any reinforced concrete floor (ground level recommended). The low profile baseplate design makes it easier and safer to load and unload large test items.